|

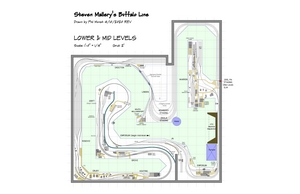

A staging yard with a 321-car capacity represents Harrisburg (Enola) on the east end of the railroad. Cars routed via PRR to eastern and western destinations travel on trains destined for Enola (staging). Also on the east end is a smaller 59-car staging yard representing Newberry PA, the connection to the Reading and New York Central railroads. Mid point on the line and half way up the helper grade is Emporium which is the junction to the Erie Branch to Erie PA. On the Erie branch is Warren Yard and 216-car staging for Erie. Finally, on the west end is a 291-car staging area representing Buffalo, NY, where the line connects to the Lehigh Valley, DL&W, NYC and South Buffalo railroads. The main yard on the model railroad is at Renovo, PA, and does classification work for most of the line. A normal operating session takes about 3 1/2 hours to complete during which approximately 27 trains run, not counting helper movements. In addition to the through freight traffic, at least five local freights originate out of Renovo serving eight stations. Several passenger trains mixed between the freights keep the Dispatcher on his toes. |

|

Even since the days of the first operating sessions in 2002, from his CTC panel, the Dispatcher controls all mainline switches. Steven built the model railroad with full electrical track circuit detection between and at all interlockings. He put resisters on the wheels at both ends of every single car on the model railroad, so his system can tell immediately whether interlockings and mainline tracks are occupied or clear. Not only can he tell where trains are, but also his safety circuits won't let the switches move while an interlocking is occupied. After starting to install some Chubb SMINI boards in late 2003, Steven held his first session using some signaling in February 2004 with three adjacent interlockings fully signaled. The effect on the background noise level just from reduced radio chatter because these signals eliminated need for as many dispatcher contacts was so noticeable that the room seemed almost too quiet to his regular crew. |

|

A total of 17 SMINI boards are installed to handle the 185 inputs and 427 outputs needed to control the complete railroad. All 15 interlockings are now completely signaled via a computer interface with the CTC panel. The computer program accepts the CTC lever positions set by the Dispatcher and the track condition indications as input. To supplement the detection-triggered switch movement protection, the program also provides software interlock protection for switches when signals clear not-yet-occupied routes across those switches. Not only are switch movements locked when a car actually occupies an interlocking, they are also locked when a signal gives permission to occupy that interlocking. The program also allows the Dispatcher to set the signal for the Renovo yard lead in fleet mode so that he doesn't have to micro-manage that track while the Yard Master needs headroom for some classification moves. Full software traffic locking in both directions is also in place! |

|

The signal aspects displayed are Clear, Approach, Stop, and Restricting, an adequate subset of the full PRR signal aspect set. When the Dispatcher selects a route and requests a clearance from his CTC panel, the program evaluates the route, currently active traffic locks, and the settings on all other signals. It then selects which signals and aspects to display if it can safely honor the request. As trains pass signals, the program makes their aspect revert to Stop. As trains vacate locked tracks, the program releases appropriate traffic locks for trains in the opposing direction. |